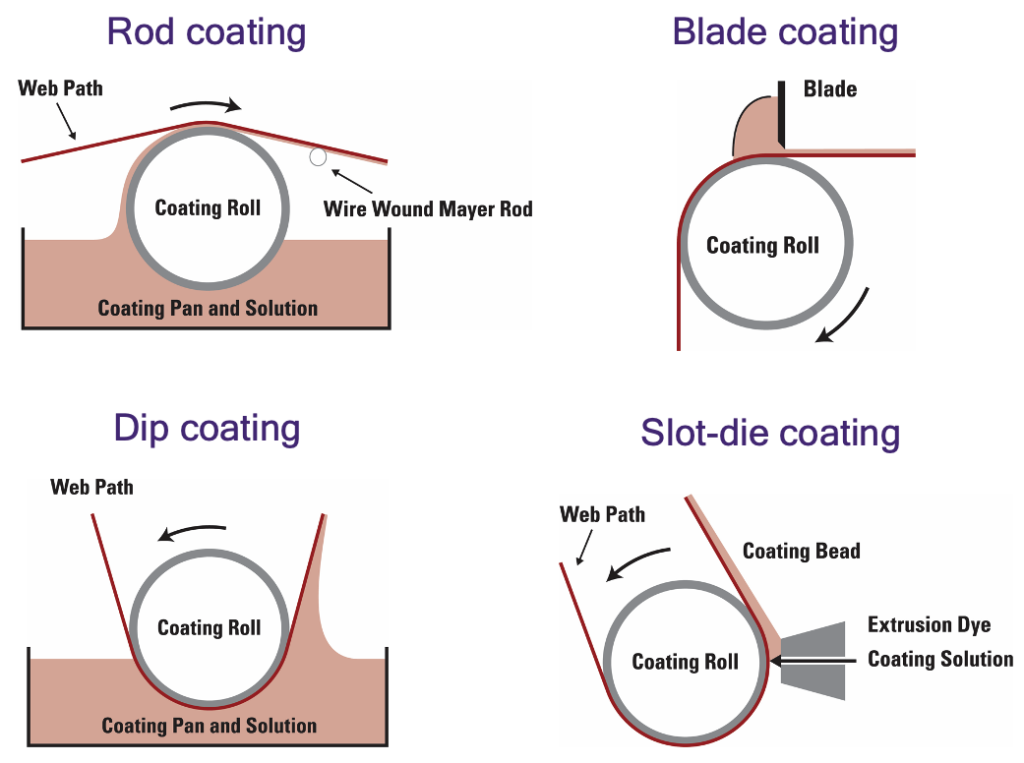

Innovation in renewable energy technologies is moving at a rapid pace, driven by growing market demand for these solutions. Much of this innovation is focused on making solutions more affordable and faster to produce. Additive manufacturing has become a leading process category for producing solar modules, batteries, and fuel cells because of high material efficiency and process scalability. One of the most effective additive manufacturing processes for cutting-edge energy technologies is slot-die coating.

Why choose slot-die coating?

Slot-die coating is perfectly suited to the production of solar cells, batteries, fuel cells, and a number of other technologies for several reasons:

Thickness control

Uniform thickness can be essential to the consistent performance of devices. Slot-die coating guarantees very uniform thickness throughout a batch by allowing operators to easily tune aspects of the process, such as ink flow rate, coating speed, etc.

Scalability

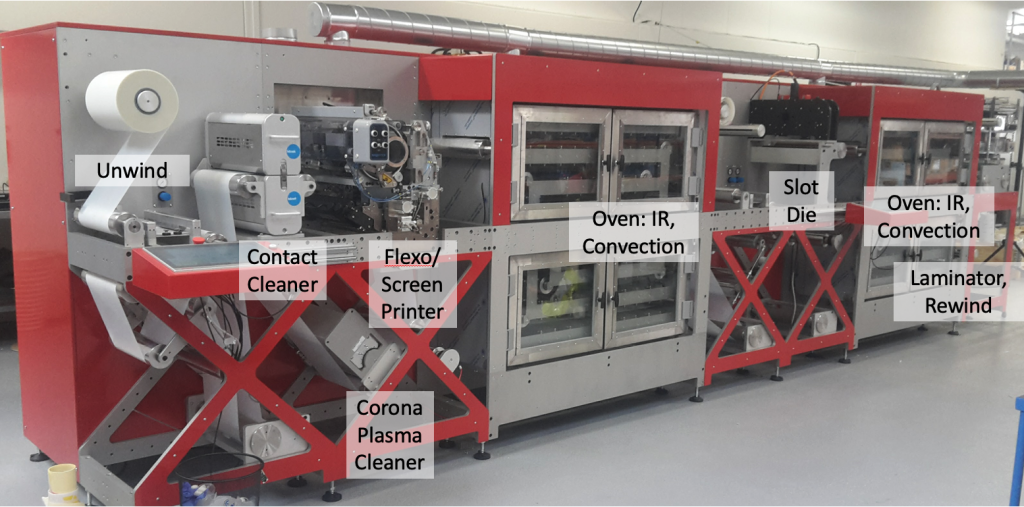

When deciding on a manufacturing process, one key consideration is how well a process can scale to high-volume production. Slot-die coating is suitable for low-volume experimentation and process development, as well as high-volume roll-to-roll manufacturing. Unlike many traditional processes such as subtractive lithography, slot-die coating can scale to your evolving throughput needs without significant changes in process design.

Material efficiency

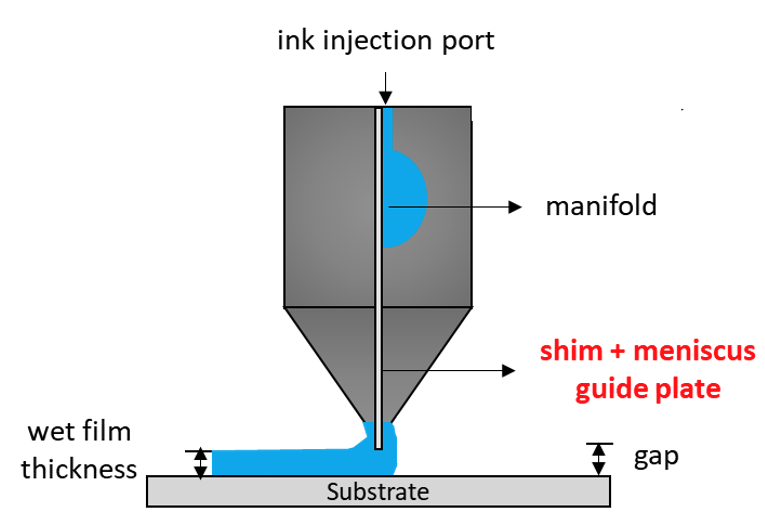

Slot-die coating produces very little waste compared with subtractive processes, and even compared with other additive processes. As seen in Figure 3 below, nearly all the coating solution required for slot-die coating is applied directly to the substrate, with minimal waste. This makes slot-die coating highly economical at scale.

Expert Advice

Slot-die coating can give renewable energy companies a competitive edge by providing consistent quality, accelerated experimentation cycles, and reduced product costs. To maximize the value that slot-die coating can have on your business, it is crucial to work in a facility that has benchtop scale equipment for process development, all the way up to roll-to-roll equipment for high-volume production runs. This ensures that processes can be reproduced and fine-tuned as your desktop innovation hits full scale.

To learn more about slot-die coating, contact the Washington Clean Energy Testbeds at wcet@uw.edu. The Testbeds offer equipment and professional expertise on many different additive manufacturing methods and can help you find the optimal process for your specific needs.