Expansion of Washington Clean Energy Testbeds will enable fabrication of pouch cells to accelerate the next generation of faster-charging, higher-energy-density, and earth-friendly batteries

Seattle, WA (October 11, 2024): The University of Washington Clean Energy Institute (CEI) unveiled plans to expand its open-access climate tech facility, the Washington Clean Energy Testbeds, to include state-of-the-art capabilities for scaled prototyping of emerging battery technologies. The new lab at the Testbeds will enable UW researchers and industry users to produce batches of pouch cells—a versatile battery format for electric transportation and beyond—to allow for development and testing at commercially-relevant scales. This capability will help drive innovation to meet the growing demand for batteries that charge faster and hold more energy using more abundant and earth-friendly materials. Industry users of the new facility retain all intellectual property, accelerating the pace that ideas get turned into market-ready products. CEI shared lab details today at an event with Washington Governor Jay Inslee, climate tech leaders, and clean energy researchers.

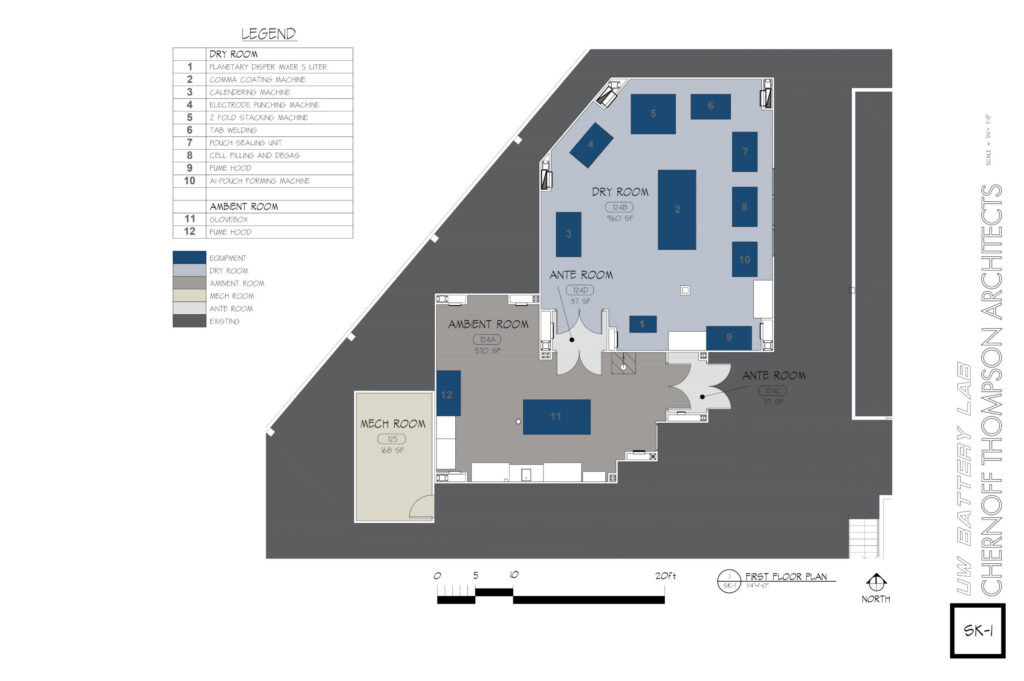

CEI opened the Testbeds near the UW campus in 2017 to provide customized training and access to instruments for fabricating prototypes, testing devices and modules, and integrating power systems. The 1,600-square-foot Testbeds expansion for batteries announced today was funded by a $7.5M capital investment from the Washington state legislature through the Climate Commitment Act. The new lab will open in summer 2025.

“Demonstrating a new battery material in a scaled, industry-relevant format is a critical step in the journey from the lab to the marketplace,” said Daniel T. Schwartz, founding director of CEI and UW Boeing-Sutter Professor of Chemical Engineering. “For exciting new materials to make it into the growing battery supply chain, they need to be demonstrated at an authentic application scale, because battery performance isn’t just a matter of chemistry, but also a large set of engineering choices at the device level. Our versatile new lab provides open access to all the equipment innovators and manufacturers need to develop leapfrog technologies that can transform EV performance, as well as key Washington sectors like aviation and heavy trucking. The lab also offers an educational resource for hands-on experiences with at-scale tools and techniques used in battery factories.”

The new battery prototyping lab will include a dry room with tools for mixing electrode slurries, coating electrodes, and the multi-step process of layering the different components inside a plastic-lined aluminum pouch; as well as an ambient room with battery cyclers and a glove box for storing battery materials. The standard-size pouch cell at the Testbeds will resemble a packet of Pop-Tarts, 83 mm wide by 122 mm long and up to 6 mm thick. Each battery will be able to hold up to 10 amp-hours of charge, a key specification for battery developers moving from the lab toward commercial production.

“The Washington Clean Energy Testbeds have already helped over 150 companies and nearly a thousand researchers take the next step in their climate tech research, development, and demonstration since opening in 2017,” said Washington Governor Jay Inslee. “With this next phase of growth, they will help innovators develop the next generation of batteries that will transform our everyday lives for the better. And by training people all across the state to become battery engineers, we can power the clean energy future with technologies made in Washington, by Washingtonians.”

Washington’s battery sector has seen significant growth in recent years. In 2022, Washington’s Group14 Technologies, the world’s largest global manufacturer and supplier of advanced silicon battery material, and Sila Nanotechnologies, a battery materials company with headquarters in California, each received $100M in grants from the U.S. Department of Energy via the Bipartisan Infrastructure Law to build next-generation materials plants for batteries in Moses Lake, WA. Combined, Group14 and Sila have raised nearly a billion dollars in private capital since the 2022 DOE investments.

“These new prototyping capabilities at the Testbeds are filling a critical need for battery innovation infrastructure in the U.S.,” said Rick Luebbe, CEO and co-founder of Group14 Technologies. “As a Testbeds user, Group14 has already benefited from open-access innovation, and we’ve also recruited several UW PhDs with top-notch clean energy training. We’re eager to explore new applications for our product at the Testbeds on our mission to electrify everything.”

The Testbeds consulted a committee of battery technology leaders to help design the lab. Members of the committee included battery researchers from the UW and Pacific Northwest National Laboratory, and research and development teams from Group14 Technologies, Paccar, Evolectric, and others.

“Our new battery lab will enable users to explore advanced manufacturing strategies to lower costs and waste,” said Devin MacKenzie, Testbeds technical director, Washington Research Foundation Professor of Clean Energy, and associate professor of materials science & engineering and mechanical engineering at the UW. “In our facility, you can quickly kick off lab work with no IP entanglement, and you can test and integrate devices under one roof — all with the guidance of our expert technical staff. You also have the opportunity to work alongside the UW’s global leaders in materials science and advanced manufacturing, as well as an incredible talent pool of UW students.”

Along with hosting an intensive hands-on course for the UW’s new Graduate Certificate in Battery Engineering, the Testbeds will host workshops for students from two-year schools around the state, including Big Bend Community College, starting in 2025. Located in Moses Lake, Big Bend Community College launched a battery training program in partnership with Sila in 2024.

“It’s imperative that we provide an up-to-date, authentic education to our students, and high-quality technical training requires proper infrastructure,” said Dr. Sara Thompson Tweedy, president of Big Bend Community College. “We’ve engaged Moses Lake companies to find out what skills they need, and this state-of-the-art lab available through the UW will help our local communities prepare to fill these exciting new jobs.”

“The Testbeds demonstrate how innovation and technology are driving growth in Washington state,” said Senator Joe Nguyễn (LD-34), chair of the Washington State Senate Environment, Energy & Technology Committee. “In Olympia, we’ve prioritized investments in open-access R&D tools that will accelerate the commercialization of advanced batteries, critical for scaling up our renewable energy capacity. While Washington benefits from some of the nation’s most affordable and clean electricity, expanding our clean energy resources will not only strengthen our economy but also ensure a sustainable, healthier future for our children.”

“The new battery lab at the Washington Clean Energy Testbeds underscores the UW’s leadership in research and innovation, and our commitment to the clean energy transition,” said UW President Ana Mari Cauce. “The pace of climate change means we need all hands on deck, which is why UW scholars across many fields and disciplines are engaging with Washington’s communities and business sectors for a more sustainable future for all.”

Washington Clean Energy Testbeds Battery Lab renderings and floor plan available here.

Media Contact:

Suzanne Offen

UW Clean Energy Institute

(240) 620-5207

soffen@uw.edu

###

University of Washington Clean Energy Institute (CEI)

CEI’s mission is to accelerate a scalable and equitable clean energy future that will improve the health and economy of our state, nation, and world. To accomplish this, it supports the advancement of next-generation solar energy and battery materials and devices, as well as their integration with systems and the grid. The Institute creates the ideas and educates the people needed to generate these innovations, while facilitating the pathways to bring them to market. www.cei.washington.edu

Washington Clean Energy Testbeds

CEI created the Washington Clean Energy Testbeds to accelerate the development, scale-up, and adoption of new clean energy and climate technologies. This open-access lab facility in Seattle, founded on the principle that users retain all intellectual property, offers customized training and use of instruments for fabricating prototypes, testing devices and modules, and integrating power systems. The facility also houses meeting and office space where users from academia and business work and collaborate. www.wcet.washington.edu