BET analysis, also known as Brunauer-Emmett-Teller analysis after the scientists who developed the method, is a technique used to measure the specific surface area of solid materials. The technique can be expanded to include other physisorption (physical coverage of a surface by atoms or molecules) methods to measure pore size and pore size distribution.

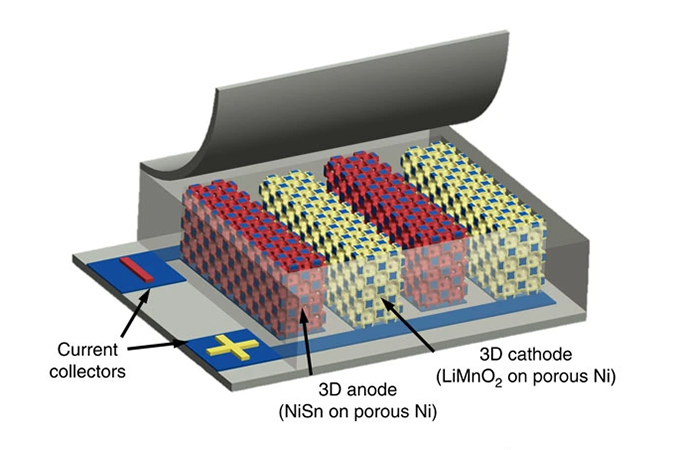

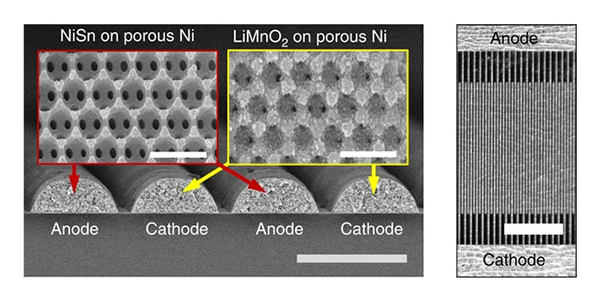

It is commonly used in materials science, chemistry, and various industries to evaluate the surface properties of porous materials and is used in battery development to characterize and optimize battery electrode materials. The surface areas of battery anodes, cathodes, and separator materials are critical to battery performance, affecting the capacity, impedance, and charge/discharge rates. For instance, higher-surface-area electrodes hold more charge. Furthermore, measuring surface area can also give manufacturers an indication of potential impurities if there are substantial variances from the expected surface area.

How it works

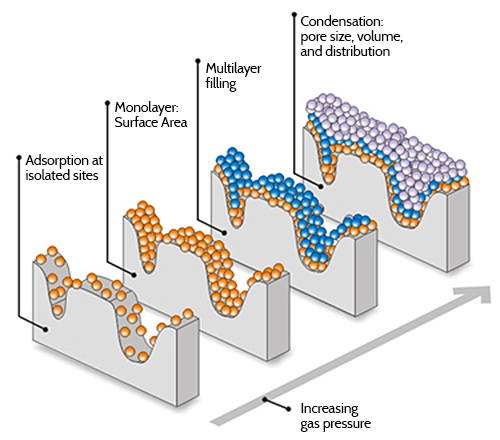

The basic principle of BET analysis involves the adsorption of a gas (typically nitrogen, argon, or carbon dioxide) onto the material at different relative pressures. The sample is exposed to increasing amounts of gas, and the amount of gas adsorbed on the surface is measured. The data is then used to calculate the specific surface area of the material.

BET analysis assumes that the gas molecules form a monolayer on the surface of the material, and the process follows the BET isotherm equation, which describes the number of molecules or atoms of a gas needed to create a monolayer of adsorbed gas on a solid surface. From this, and based on the size of the gas molecule or atom, the surface area of the sample material can be calculated.

The specific surface area is calculated by plotting the relative pressure against the quantity of gas adsorbed and fitting the data to a line, the slope of which provides information about the specific surface area.

In addition to measuring surface area, modern physisorption systems can measure material porosity using other calculation methods. Micropores, less than 2 nanometers, and mesopores, 2 to 50 nanometers, are crucial factors in battery materials that can affect properties such as electrolyte transport, active electrode sites, conductivity, and charge carrier intercalation. To truly understand and optimize battery component performance and that of many other critical materials and components in other applications, it is critical to measure both surface area and the size and density of pores.

Expert Advice

To learn more about BET and physisorption testing resources, contact the Washington Clean Energy Testbeds at wcet@uw.edu. The Testbeds offer equipment and professional expertise on many different manufacturing and testing methods, and can help you find the optimal process for your specific needs.